Case Study - Compostable Pouches

How BakPac provided a 100% compostable packaging solution for a new product launchCase Study – Compostable Pouches

By design, digitally printed pouches are a more sustainable option than conventionally produced pouches or rigid packaging.

The reduction in raw materials required, lower energy used in production and minimal waste created, provide the best sustainable option for customers looking for more environmentally friendly packaging.

For those that wish to take their green efforts a bit further, we can also produce pouches using recyclable or compostable materials. We learned a lot during production of our first 100% compostable pouch job earlier this year.

Customer and Product

Jan Keating, Gorilla Superfood Powder

Who are they and what do they do?

Jan Keating is a qualified naturopath and herbalist and a registered member of the Irish Naturopaths Association and the Irish Register of Herbalists. A naturopath is a GP of natural medicines, nutrition, and general health. Jan runs the Seapoint Clinic of Naturopathic Medicine

Tell us about your product – what is it, how did you develop it and do you produce it yourself?

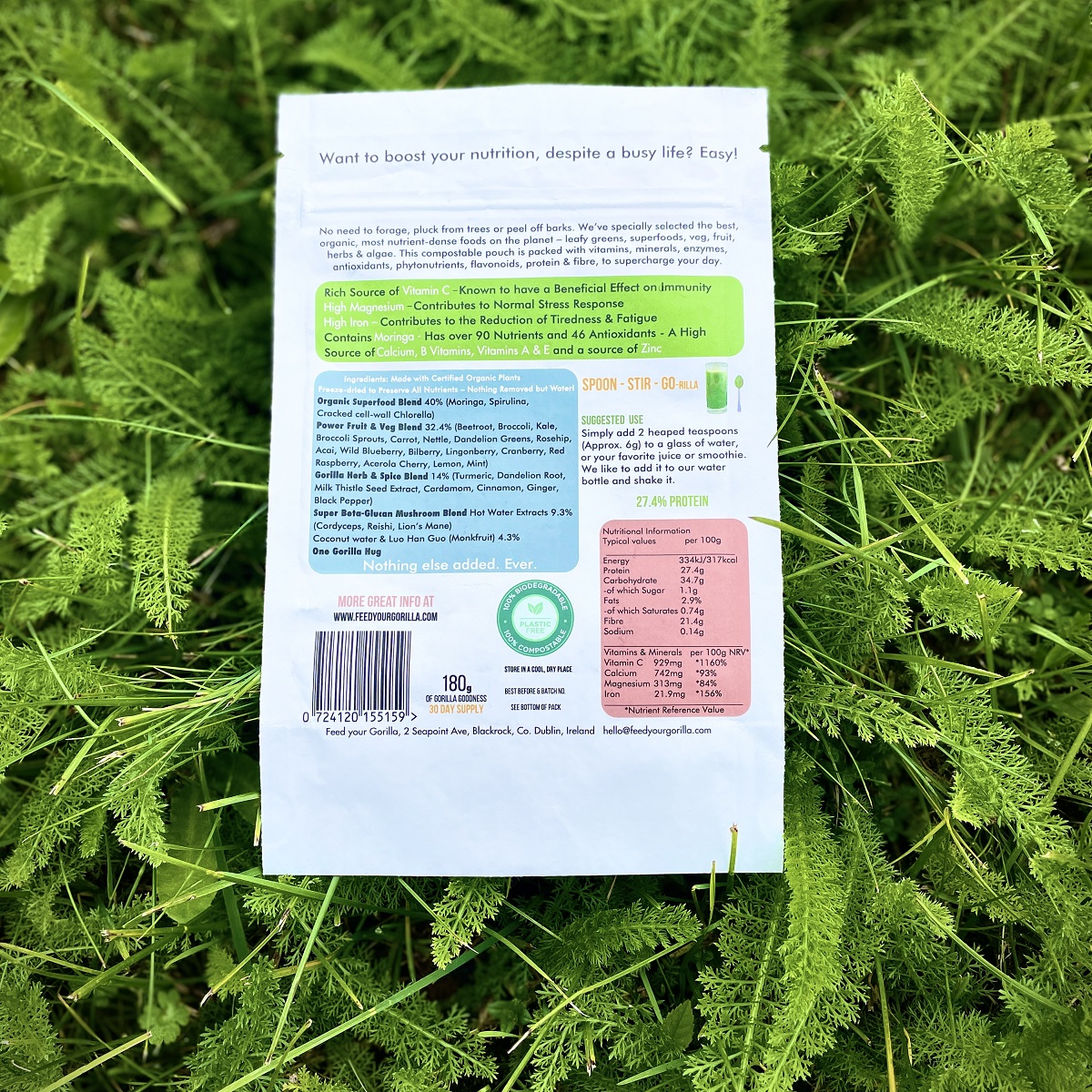

“Gorilla Superfood Powder is an energizing blend of leafy greens, fruit, vegetables, herbs, micro-algae, mushrooms and superfoods. Unlike other similar products, Gorilla Superfood Powder is cereal–grass and sugar free.

I wanted to create a product to meet customers’ needs of wanting to eat healthier but making it easier. You just need 2 teaspoons / 6g in a glass of water a day. There is so much good nutrition available from the natural foods we can eat but not everyone knows what to eat, or they always eat the same thing without variety. I was determined to create a clean, natural and truly gluten free product. There are a lot of people with sensitivities so producing something that avoids most intolerances was important.

I couldn’t make it if it wasn’t clean. I chose ingredients that pretty much everyone could tolerate including things that grow around us such as nettles and dandelions.”

Jan spent 8 eight years researching and personally sources all ingredients, ensuring they are sustainably sourced.

Who is your target market?

“The health-conscious market that are currently looking for something like this and eventually to target those who need to improve their health and don’t eat enough fruit and vegetables.”

Why it was important to you to package the product in a compostable pouch rather than a standard pouch or rigid packaging?

I was determined to find a sustainable solution that wouldn’t add to the plastic in the world. I had to be true to myself and my beliefs when packaging the product.

How did you hear about BakPac?

I needed a packaging company that could produce 2000 pouches. I was launching a brand new product so needed to test the market with a relatively small quantity. When I approached another packaging company, the quantity was too small for their minimum order. They referred me to BakPac, one of their trade partners.

Were the BakPac team helpful in guiding you through the initial steps?

Extremely helpful and supportive. They were also super-fast! I had the pouches just 2 weeks after initial contact.

Phil Smith is the General Manager at BakPac. He and the team worked closely with Jan Keating to produce the packaging she required.

How does the construction of a compostable pouch differ to that of a standard pouch?

The main difference is the material we use. Standard pouch materials are made up of different layers of plastic polymer materials. Our compostable pouch material is made from layers of paper and cellulose plant based materials. The materials are also PLA free which guarantees that they will home compost within the regulatory timescales.

Barrier properties differ to our standard materials. The compostable material has gas barrier properties similar to a metallised PET and very good moisture barrier properties making very close to standard products in how it protects products.

The HP Indigo print process does have some limitation in combination with this material. It is best to try and avoid putting heavy dark colours in the heat seal areas of the pouch as some discoloration may occur. This is due to the ink being on the surface of the pouch and not behind a layer of protective lamination that would stop the pouch from being compostable. Standard material pouches would have a thermally laminated layer that helps to protect the ink.

Download our compostable artwork guidelines

Are there any other solutions to these limitations?

We know that we need to be able to offer customers a solution to this so have invested in additional coating equipment to improve this process. With the addition of the ABG Digicon 3000 later this year we will be able to produce compostable pouches with ink coverage that can expand to the edges without discolouration.

What did the BakPac team learn from the job that you have taken forward for future customers?

We had done a lot of R & D with compostable materials but working on our first actual job increased our knowledge of how the material behaved during conversion. We learned that the cut down the side is rough with compostable material, so lighter colours look better on the finished product.

Due to working directly with the customer, artwork changes were able to be made to fit the pouch better. We learned a lot about artwork limitations with compostable materials. Gorilla Superfood Powder was the perfect design for a compostable pouch.

I would recommend BakPac 1000%. They were extremely helpful, supportive, super-fast (2 weeks) after 18 weeks of waiting for another company. I’m very happy with the pouches – they look and feel great.

Do you want compostable pouches?

Get in touch with our team if you are looking for short to medium runs of compostable or recyclable pouches.