BakPac is growing – fast

This month our newly expanded production facility in Brentwood, is taking delivery of two more Galaxy Packtech pouchmakers to join our high-performance lineup.

But what does this really mean for brands, trade partners, and the future of flexible packaging in the UK? We caught up with our Operations Manager, Phil Smith, to find out.

About the Installation and Expansion

Q: With three pouch converters already, can you tell us what these two new Galaxy Packtech pouchmakers will bring to BakPac’s production capabilities?

A: These two new pouch machines represent a significant increase in our production capacity. We’re committed to maintaining fast lead times and high quality, and we never want to be in a position where capacity holds us back. Going from three to five pouchmakers allows us to stay ahead of demand and continue delivering excellent service.

Q: How will this expansion impact lead times, volume capacity, or overall efficiency?

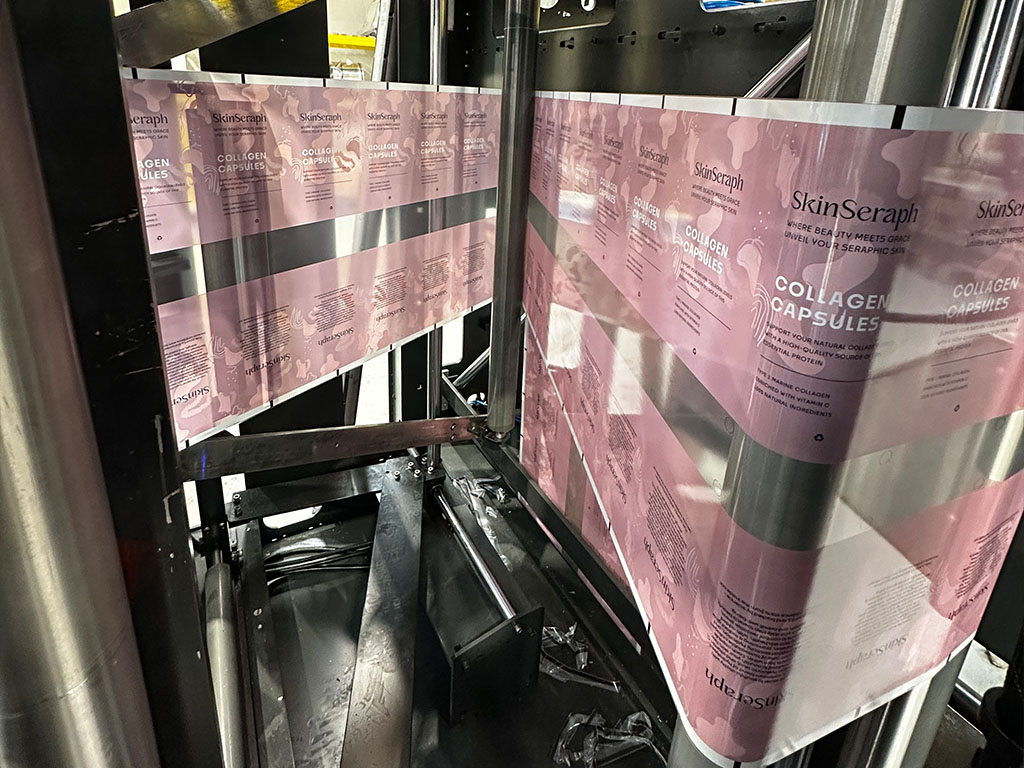

A: We still handle very short runs – sometimes as little as 500 pouches – but we’re increasingly seeing jobs in the hundreds of thousands. That demands equipment capable of running continuously. These new machines are designed with features like non-stop reel changeovers, allowing us to switch materials without halting production. This helps us maintain our 7–10 day lead times, and sometimes we can deliver even faster. The additional capacity prevents bottlenecks and gives us the flexibility to schedule machine maintenance without affecting production.

Q: What’s changed within the new factory space to accommodate these machines and our growing pouch production?

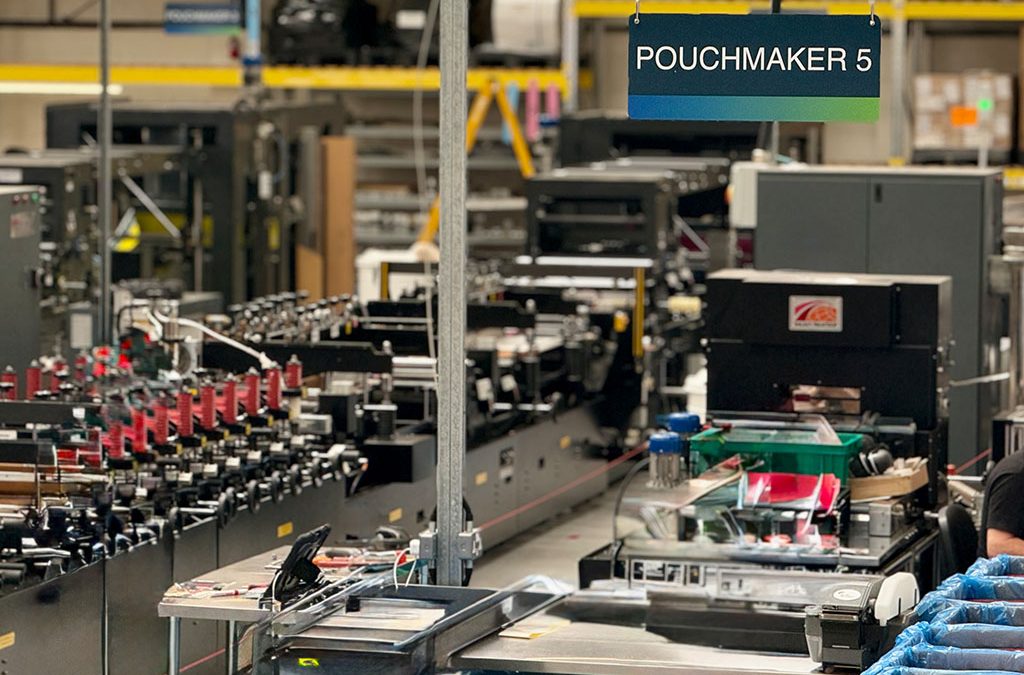

A: We’ve renumbered the machines to reflect their position in the factory—so the fourth machine is named Pouchmaker 3. Originally, we planned for four machines across the floor, thinking we had plenty of space. As demand has grown, we’ve reconfigured the layout and utilities, particularly power, to accommodate five machines. It took some careful planning, but we’ve made it work while ensuring enough room for operators and materials handling. With these changes, the factory can now house five pouchmakers comfortably—giving us a significant production boost.

Customer Benefits

Q: What types of pouches or features will these new machines help us produce more efficiently?

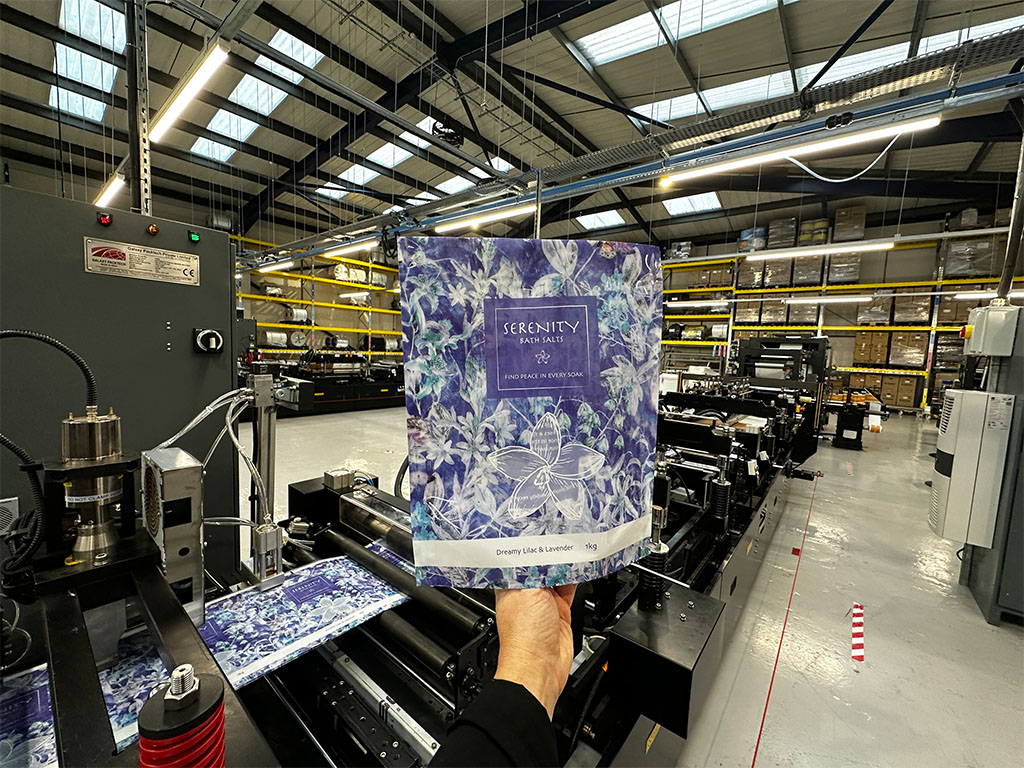

A: While they increase our capacity for standard pouches, these machines also offer enhanced sealing capabilities, which is especially beneficial for MONO-material products. These single-polymer materials are more challenging to convert than traditional multi-layer films. The new sealing features give us more control over temperature, dwell time, and pressure—resulting in faster run speeds, better stability, and higher-quality output.

Q: From a customer’s point of view, what are the main advantages they’ll see as a result of this investment?

A: Customers will benefit from more consistent product quality and reduced lead times. With greater efficiency and fewer production bottlenecks, we can get work through the factory faster while maintaining excellent quality.

Discover the MONO range for fully recyclable pouches

Production and Quality Control

Q: How do we ensure consistent quality when scaling up production like this?

A: Quality is always our priority. Before installation, we trained our staff and reinforced our SOPs. Each pouch line has trained packers who know exactly what to look for and maintain clear communication with the machine operators. This teamwork ensures issues are caught early. The additional capacity also means we can scale up production without overloading our team—we’re already preparing to run all five machines smoothly.

Q: How do the Galaxy Packtech machines compare to other equipment in terms of performance, flexibility, or reliability?

A: Galaxy machines are built on a solid engineering foundation. Their innovation comes from close collaboration with us—they observe, ask questions, and continually improve the machines based on how we use them. The mechanical pressure system is highly consistent, and their advanced web management is perfectly suited for digital production. That’s critical for us, as we’re still doing many short-to-medium runs. The machines use sensors to monitor every part of the pouch—from Doy seals to zips and punches—ensuring accuracy and stability, particularly with the more demanding MONO materials. This built-in intelligence supports quality while keeping make-ready times short and efficient.

Innovation and Future Readiness

Q: Do you think the industry is shifting in a way that makes this kind of investment essential for future growth?

A: Absolutely. The market demands faster turnarounds and greater flexibility. With our two HP Indigo 200K presses, we can print a huge volume in a short time – so we need pouch conversion to match that pace. Brands today want the ability to test and adapt packaging quickly, especially smaller and fast-growing ones. These new machines give us the agility to serve that market, while also supporting larger, steady runs. The combination of high-speed digital print and scalable pouch conversion is key to our future growth.

Marketing and Industry Visibility

Q: What makes BakPac stand out among UK flexible packaging manufacturers right now?

A: We’re one of the most technologically advanced sites in the UK. Not only do we have the country’s only HP Indigo 200K – but we have two. Since the arrival of our first Galaxy pouchmaker in mid-2023, we’ve continued to invest in the latest tech, enabling us to deliver top-quality digital pouch production.

Q: Why should print partners or brands looking for pouches be paying attention to what we’re doing here?

A: Because we combine cutting-edge technology with exceptional service. We’ve got serious print power, highly advanced pouch-making equipment, and a lot of capacity. But we also have a customer-first attitude, technical expertise, and a deep understanding of the market – from material selection to sustainability. Brands can trust us to meet their lead time, quality, and environmental requirements.

Q: If you could send one message to a brand or trade customer about BakPac, what would it be?

A: At BakPac, we take care of your brand from the first enquiry to delivery. We know your packaging represents your business, and we treat it with the respect it deserves. We’re a UK-based, privately owned company with the best technology and a team that genuinely cares. Come and experience what we can do—buy your pouches from us!

Conclusion

BakPac’s latest investment in two new Galaxy Packtech pouchmakers marks a bold step forward in capacity, efficiency, and quality. With a growing demand for sustainable, digitally printed pouches and ever-shorter lead times, this expansion future-proofs our ability to serve both emerging and established brands. The combination of cutting-edge print technology, enhanced sealing capabilities, and a passionate, well-trained team makes BakPac one of the most capable and responsive flexible packaging manufacturers in the UK.

Join Us on This Exciting Journey

As we continue to push the boundaries of flexible packaging, we invite you to explore our offerings and see how our latest advancements can benefit your products.

At BakPac, the sky isn’t the limit—it’s just the beginning.

BakPac is the flexible packaging division of Bakers, an independent, family run label printer established in 1973.

If you’re looking for quality self-adhesive labels for your products then get in touch with our team.

- sales@bakerlabels.co.uk

- 01277 281 900

- www.bakerlabels.co.uk