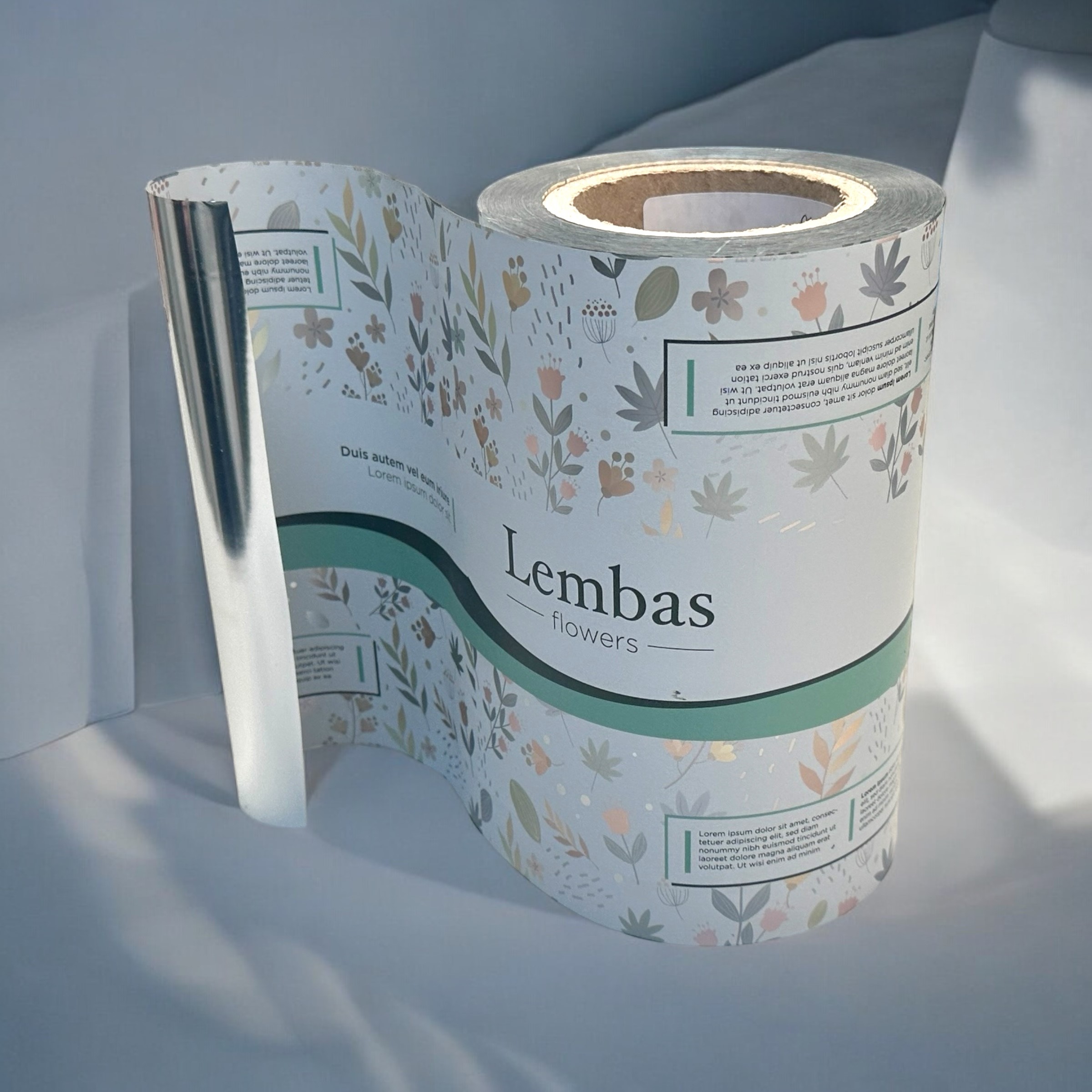

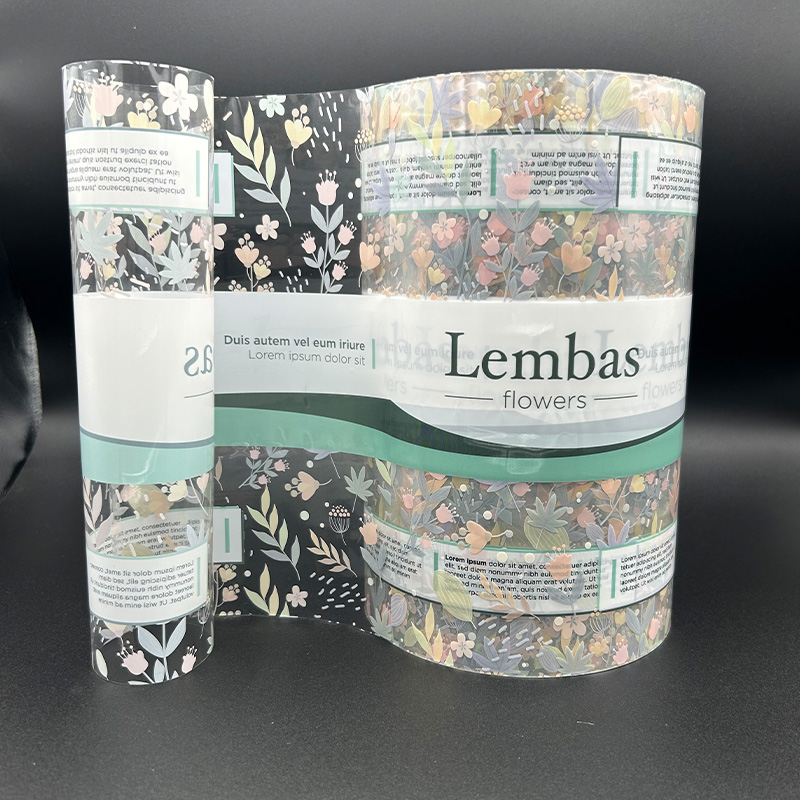

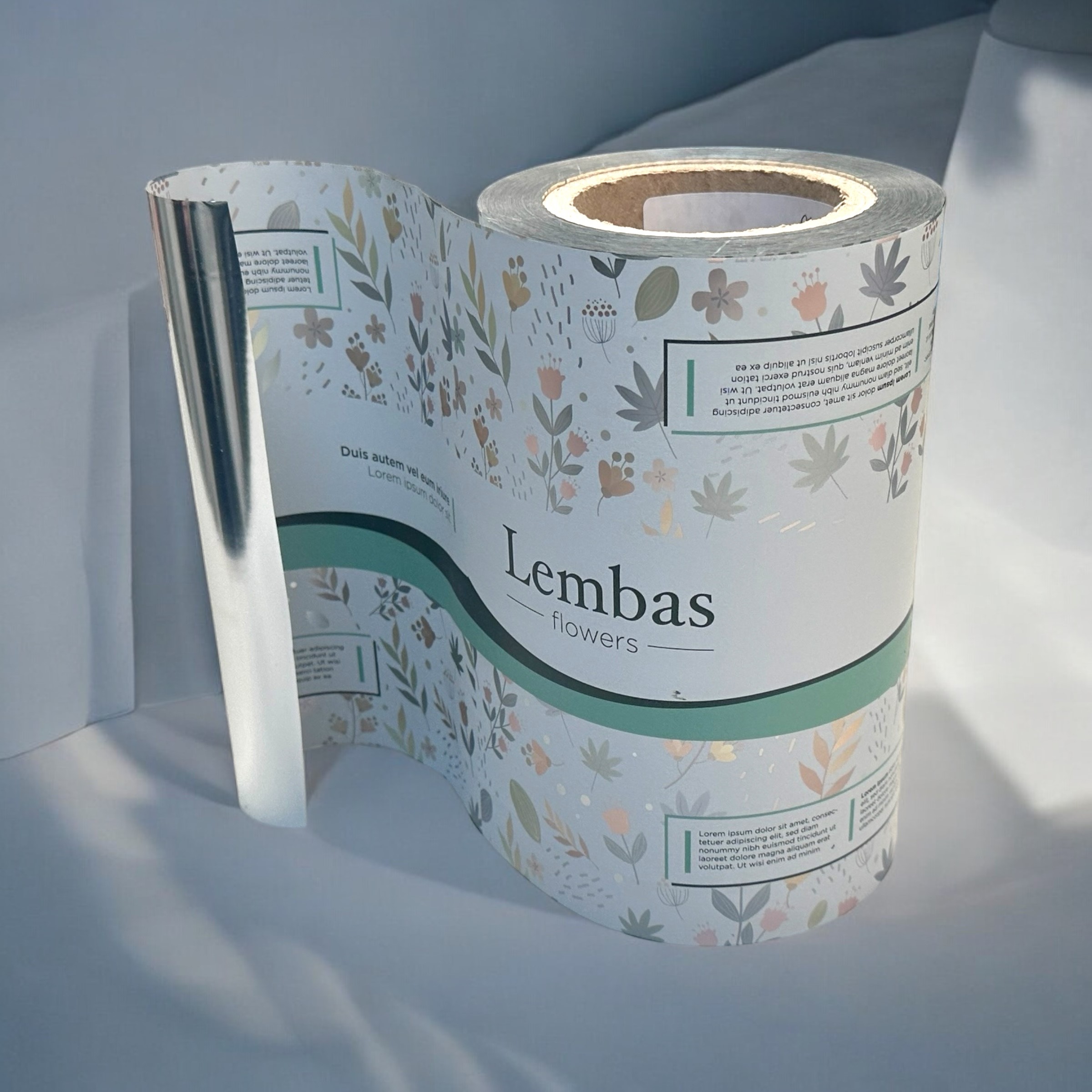

Printed Film for Packaging

Request SamplesWhat is Printed Film?

Printed film (aka flexible film, flow wrap film or roll stock packaging) is a versatile and high-performance flexible packaging material that comes on a roll and is used in form, fill, and seal (FFS) machines. It is pre-printed with custom designs, branding, and product information, making it a cost-effective and efficient way to package a wide range of products. Unlike pre-made pouches, printed film is fed through automated machinery, formed into packaging, filled with product, and sealed all in one process. This makes it ideal for high-speed production lines. Want to a FFS machine in action? Autopak Machinery has a great video here showing their Form Fill Seal machine doings its thing.

Request a free Sample Pack

Feel the quality and see the impressive print quality for yourself with our sample packs

What is Printed Film Used For?

Multiple industries use printed film widely but is most commonly found in:

- Food & Confectionery: Chocolate bars, protein bars, crisps, snack foods

- Coffee & Tea: Ground coffee, coffee beans, single-serve sachets

- Powders: Electrolytes, protein powders, energy boosters

- Pet Food: Dry food, treats, and supplements

- Personal Care: Sachets for shampoos, lotions, wipes, and cosmetics

- Medical & Pharmaceutical: Single-use medicine sachets and test kits

Why Choose Printed Film?

Businesses choose printed film because it is:

- Cost-Effective: It reduces waste and speeds up production.

- Lightweight & Space-Saving: Ideal for large-scale production without storage issues.

- Customisable: Available in different materials, finishes, and barrier properties.

- Seamless Branding: High-quality printing ensures strong shelf presence.

- Sustainable Options Available: Recyclable and compostable alternatives exist.

- Designed for Speed & Efficiency: Printed film is made for high-speed flow wrapping and packaging lines, ensuring smooth production and reducing material waste.

Its versatility means brands can use it for everything from solid foods to liquids and everything in between.

Most Popular Materials & Finishes

The most commonly used material for printed film is metallised film with a matt finish.

Brands prefer this combination because it provides:

Barrier Protection: Keeps moisture, oxygen, and light out, preserving freshness.

Premium Look & Feel: Matt finishes give a soft-touch, high-end appearance.

Durability: Resistant to tearing and punctures.

Sealing Performance: Different films work with fin or lap seals, depending on packaging requirements.

However, we also offer a range of other materials and finishes depending on specific needs:

- BOPP (Biaxially Oriented Polypropylene): Great for clear, glossy, or matt finishes.

- PET (Polyethylene Terephthalate): High clarity and strength, good for premium packaging.

- PE (Polyethylene): Flexible, often used for sachets and pouches.

- Paper-Effect Finishes: A growing trend for brands wanting a more natural, eco-friendly look.

- Soft-Touch or Tactile Finishes: For luxury branding appeal.

Each finish and material affects how the packaging looks, feels, and performs in terms of protection and usability.

End Products

Printed film is a go-to packaging solution for industries requiring high-speed production and extended shelf life. The end products that can be created from printed film include:

Flow Wraps

For Bars, Biscuits and Chocolates

Sachets

For Powders, Liquids and Creams

Converted Pouches

Stand-up, resealable, or flat-bottom pouches

Stick Packs

For single-use energy powders and drink mixes

Sustainability & Mono-Material Printed Film

Sustainability is a growing focus in packaging, and mono-material printed film is becoming a preferred choice for brands looking to reduce their environmental impact. Mono PP (Polypropylene) films offer recyclability and give brands an ideal alternative to traditional mixed-material films that can be harder to process in recycling streams.

Brands choosing mono material packaging benefit from:

Easier recyclability: Standard recycling facilities can process them.

Reduced environmental footprint: Fewer materials mean less waste.

Consumer appeal: More brands are marketing their packaging as “100% recyclable”.

If you’re looking for sustainable flexible packaging, mono-material printed film is a great option without compromising on performance or design.

Digital Print: A Smarter Step Toward Sustainability

Alongside mono-material packaging, digital print adds another layer of eco-friendly advantage. With high-performance technology like the HP Indigo 200K, brands can produce flexible packaging that’s faster, cleaner, and far more efficient – without compromising on quality or creativity.

Smart Savings, Less Waste

-

Minimise inventory and print only what you need

-

Avoid excess with volume-based, on-demand production

-

Cut costs on packaging that might otherwise go unused

-

Easily test markets without overcommitting

Safer, Faster, More Agile

- Always use the latest version of your packaging design

- Slash time-to-market and react quickly to changes

- Maintain consistent branding with global colour control

- Add anti-counterfeit features and meet compliance needs

More Meaningful for Customers

-

Create region-specific designs with localised content

-

Run cause- or event-driven promotions

-

Enable last-minute changes with late-stage differentiation

-

Adapt across a product’s life cycle to stay relevant

Greener by Design

-

Cut back on packaging waste and overproduction

-

Lower your carbon footprint

-

Eliminate hazardous chemicals from the process

-

Reduce energy use with more efficient workflows

Smarter Supply Chains

-

Add track & trace and serialisation for better control

-

Simplify revision management

-

Support just-in-time production and leaner distribution

What’s Next?

Printed film is an essential packaging solution for businesses looking for a cost-effective, high-speed, and customisable option. If you’re considering printed film for your brand, let’s talk! Our team can help you choose the right materials, finishes, and formats to ensure your products stand out while staying protected.

Ready to take your packaging to the next level?

Get in touch with us to explore how our innovative features can work for you.