Labels VS Pouches: What’s the Difference - and Why It Matters

Request SamplesLet’s be honest – labels have been the backbone of product packaging for decades. They’re the finishing touch on bottles, jars, tubs, and tubes across every supermarket shelf. But as consumer demands shift and sustainability climbs higher up the priority list, a new player has stepped up to the plate: digitally printed pouches.

We’re not here to cancel labels (far from it). In fact, they’re still essential in loads of applications. But when it comes to speed, sustainability, and shelf appeal? Pouches are packing a punch – and they’re changing the packaging game for good.

So, let’s unpack it: where do labels shine, where are pouches taking over, and how can brands choose the best option for their product?

Request a free Sample Pack

Feel the quality and see the impressive print quality for yourself with our sample packs

A Brief History of Labels

Labels have been around since the 1700s – starting with hand-printed wine labels before evolving into gummed paper and, eventually, self-adhesive stickers. Fast-forward to today, and labels come in every shape, finish, and texture imaginable. They’re applied to rigid containers, glass, metal, and even other forms of flexible packaging.

For certain formats (especially luxury goods, refill containers, or custom rigid packaging) labels remain a go-to. Think shampoo bottles, essential oil droppers, wine/spirits or artisan jams. You’ll often see tactile finishes, metallic foils, and specialist stocks that scream quality.

But labels have limits. You’re often working with a small surface area and multiple components.

The Rise of Digitally Printed Flexible Packaging

Flexible packaging isn’t new – but digitally printed flexible packaging is redefining how brands operate. Unlike labels, where design is printed separately and applied manually or mechanically, digital pouches are printed directly onto the packaging film, giving full coverage and flexibility without plates, tooling, or sticky backing.

At BakPac, we’re proud to run two HP Indigo 200K digital presses – the only company with the power of two currently in the UK. They represent the next level of print innovation, allowing us to deliver vibrant, high-quality packaging with incredible speed, accuracy, and flexibility.

The Print Industry’s Shift

The packaging print industry has been dominated by analogue processes for decades – flexo being the traditional workhorse. These methods rely on physical plates and long lead times, making them inefficient for short runs or frequent design changes.

But the print world is changing. Digital printing now makes up a fast-growing segment of the market, thanks to its ability to:

- Eliminate plates and tooling costs

- Reduce waste through just-in-time production

- Deliver customisation and versioning with zero added setup time

- Match the speed of changing consumer demands and product launches

For packaging, this shift is critical. Brands can trial new SKUs, test markets, personalise runs, and scale production without the waste and wait of old-school methods. It’s print, evolved – and it’s what today’s brands need.

Market Stats and Trends

The move to flexi-pack isn’t just a trend—it’s a transformation backed by data:

- The flexible packaging market is growing at 4.7% annually (Smithers)

- Refill formats using pouches can cut material waste by 35–70% (Packaging Tech Today)

- 49% of brands are using or exploring flexible formats to meet sustainability goals (Kearney)

- The global digitally printed pouch market is forecast to hit $28.7 billion by 2033 (Law Print Pack)

Why Flexible Packaging Is Taking Over

Sustainability

Flexible packs are typically lighter than rigid containers, use fewer materials, and reduce overall emissions. Many are now designed to be recyclable or made from mono-materials to suit evolving waste systems.

Branding and Real Estate

A label might give you a front and back panel. A digitally printed pouch gives you front, back, sides, gussets, and seals. That’s room for bold branding, storytelling, and compliance info – all in one sleek design.

Agility and Lead Times

Digital pouches can go from artwork to production in days – not weeks. No plates. No waiting. Perfect for seasonal designs, trial runs, or fast-moving SKUs.

Transport and Storage

Flexible formats save space in transit and in the warehouse. They’re lightweight and compact, which cuts down on shipping costs and reduces environmental impact.

Changing Consumer Behaviour

As refill culture grows and sustainability drives buying decisions, pouches offer a lighter, lower-waste solution that aligns with consumer expectations. From supplements to household cleaners, the shift is on.

When Labels Still Make Sense

Labels remain a powerful packaging tool – especially when:

The container is rigid, reusable, or premium

The finish is part of the appeal (foil or varnish)

Require space for regulatory or extended product information

Refill systems are a perfect example: the refill comes in a pouch, but the primary container? Still labelled. The two formats can (and do) coexist.

Need help navigating the choice between labels and pouches?

We’ll help you flex in the right direction.

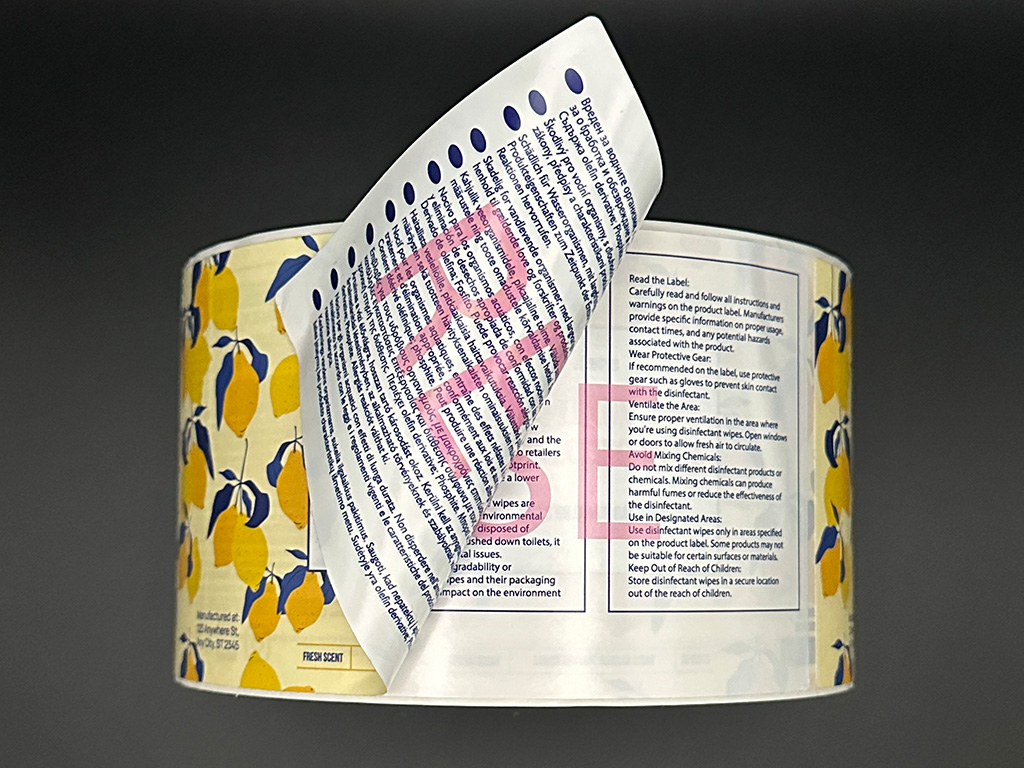

Labels on Pouches vs Digitally Printed Pouches

It’s worth pausing on one common middle ground: labels applied to pouches. Many brands starting out in flexible packaging use blank or generic pouches and apply printed labels for branding. It’s a handy entry point (especially for very short runs or test batches) but it does have its limits.

While label-on-pouch keeps initial costs low, it often lacks the polish and cohesion of fully printed packaging. You’re restricted to the size and shape of the label, meaning your design space is limited. There can also be issues with adhesion, creasing, or durability – especially if the pouch is handled frequently or exposed to moisture.

In contrast, digitally printed pouches give you complete control. The design is printed directly onto the pouch film, covering every panel seamlessly – no peeling, no bubbling, and no extra application step. It’s faster, cleaner, and more scalable – with zero need for labels, stockpiles, or stickering time.

If you’re using labels on pouches today and looking to level up, digital pouches are the natural next step. You get the same agility, but with better branding, lower unit costs at scale, and a much more professional finish.

Choosing What’s Right

It’s not about one format replacing the other – it’s about making the right choice for your product, brand, and market. You might even use both together across your range.

- Launching a new direct-to-consumer product? A digitally printed pouch gets you to market faster.

- Selling in luxury retail? A rigid container with a premium label could be the best fit.

- Building a refillable system? Use pouches for refills and labels for the containers.

- Want to reduce waste, increase impact, and streamline supply? Flexible packaging ticks all the boxes.

Final Thoughts

Labels and pouches each bring something to the table – but for brands looking to scale smarter, meet sustainability goals, and stand out on the shelf, digitally printed flexible packaging is proving to be the future.

With technology like our HP 200Ks, the print industry is moving fast – and BakPac is right at the forefront.

GET A QUOTE

"*" indicates required fields

Looking for Labels?

We’ve been producing professional, high quality labels for decades so if it’s labels you need then head to Baker Labels for the very best.