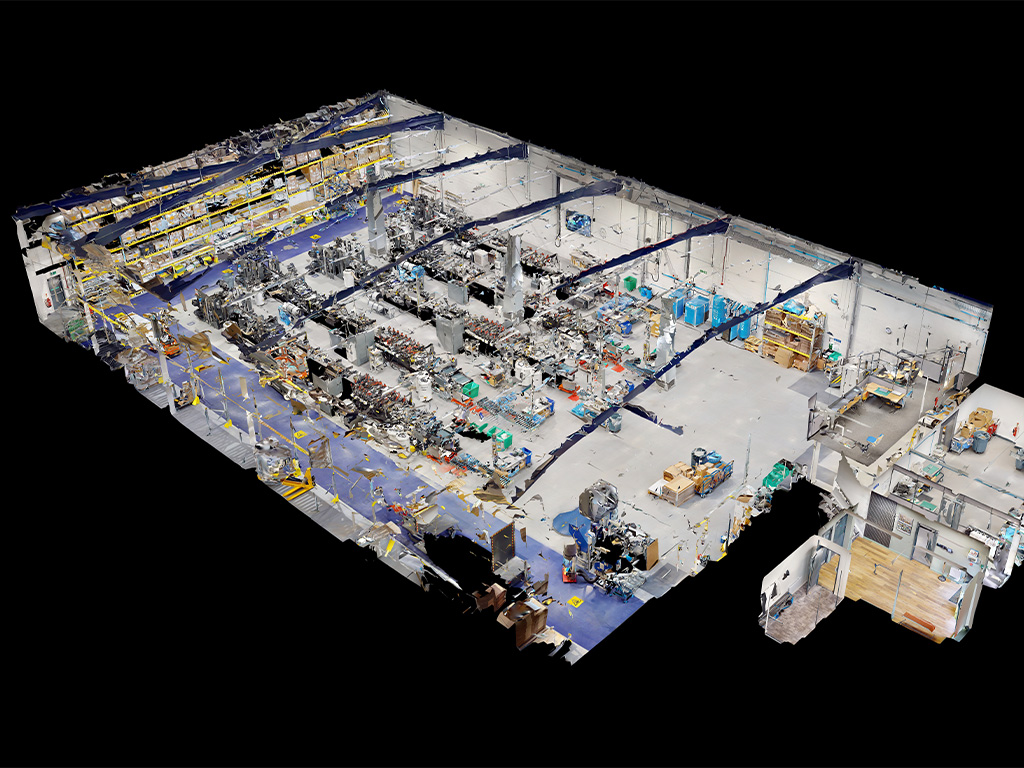

Our Flexible Packaging Equipment

Discover the flexible packaging equipment we use to produce high quality, fast speed to market pouches, sachets and printed film here in the UK.

Tech Specs

Printing Speed

56m/min in EPM; 42m/min in 4-color mode; 33m/min in 5-colour mode

Image Size

746 x 1120 mm

Substrate Thickness

10 to 400 microns

Web Width

Max 762mm | Min 400mm

Custom Pouch Printing on HP Indigo 200Ks

Our first HP Indigo 200K was installed in January 2024 replacing the original Indigo 20000 installed in 2019. Our 2nd 200K press was installed in November the same year, doubling down on print power.

Stepping into the heart of BakPac’s operations, the 200Ks boast a 30% increase in printing speed and a staggering 45% boost in expected productivity. This isn’t just about numbers; it’s about pushing boundaries in packaging manufacturing, with quicker turnarounds, unparalleled efficiency, and the ability to handle diverse printing requirements with ease.

Enhancements

• Efficient energy consumption and improved corona treatment for a cleaner, greener footprint.

• A new writing head laser system propelling print speeds to new heights.

• Bid Motors revolutionising colour uniformity, consistency, reliability, and lifespan.

• The Ink delivery system with 5 dual revolver stations supporting 100% coverage and non-stop printing

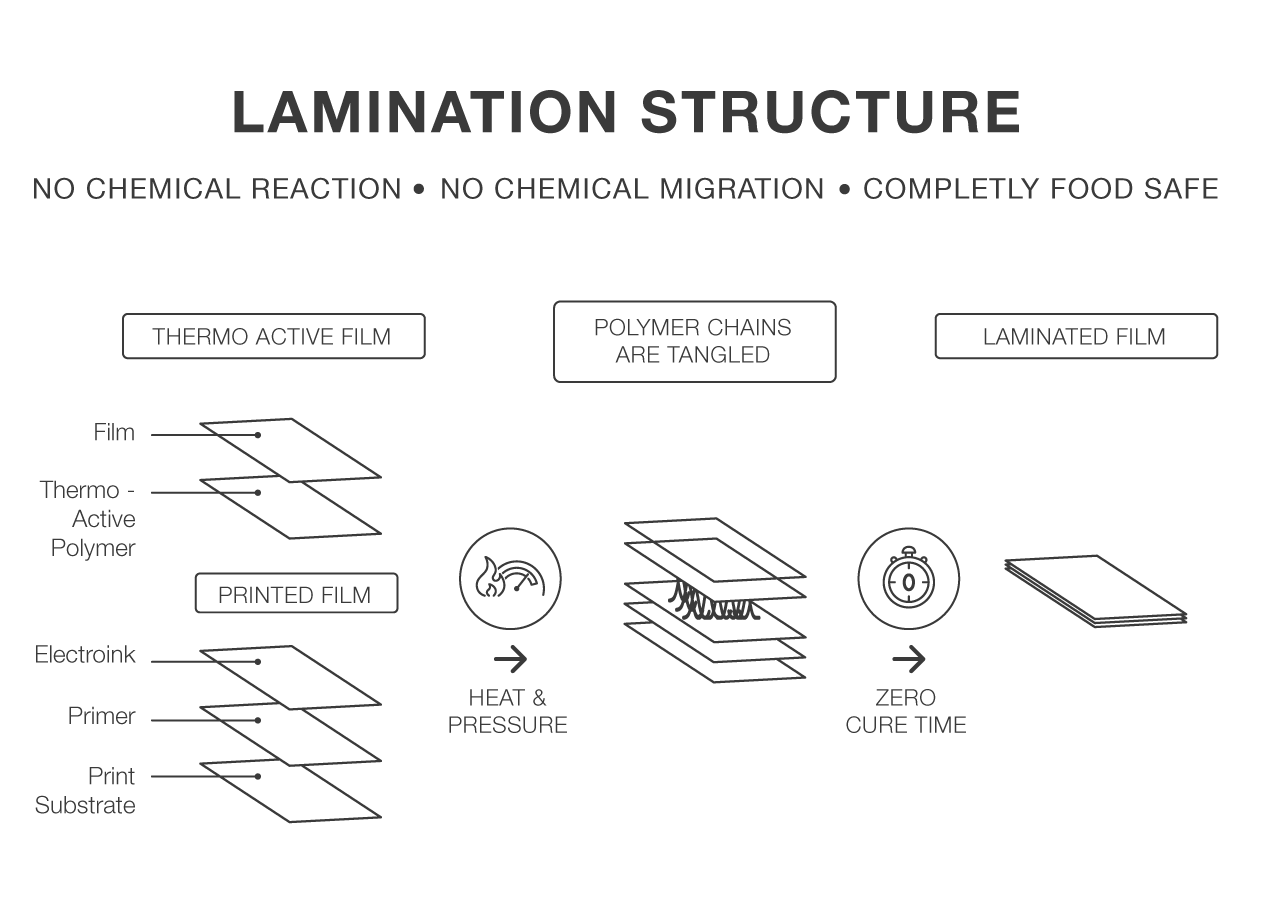

Laminating on an Enprom Thermal Laminator

The Enprom Thermolaminating machine has been specially designed for flexible packaging markets, pouches and adding value to the quality finishing of the products.

The compact solution is composed of two stages joined with a web path bridge. The first unit supports two unwinders with its control tension units and corona treatment. The second unit contains the rewinder and laminator unit. The machine is rigidly joined by four union beams. The new development of this solution has been designed with the goal of shortening the web path to a maximum and thus reducing waste by up to 33%.

Click to view

Tech Specs

Machine Model GS-24 Plus 200QS

The Machine is suitable for making the following pouches:

➢ Three Side Seal Pouch

➢ Three Side Seal Pouch with Zipper

➢ Stand – Up Pouch

➢ Stand – Up Pouch with Zipper

➢ Both Side Gusset Pouch

Pouch converting on a Galaxy Packtech Pouchmakers

Our 1st Galaxy Packtech pouch maker was installed into our pouch factory in September 2023, bringing a new level of quality to our flexible packaging conversion capabilities.

By May 2025 we had expanded our pouch production floor to hold FIVE Galaxy pouchmakers. The mechanical strength has brought improved strength to heat seals, higher conversion speeds and leaner set ups. Optomised for mono-materials, the Galaxy pouchmakers handles thicker material constructions beautifully.

Digital Advantages

Reduce Cost

- Minimum inventory

- Volume-based on demand

- Reduce obsolescence

- Market testing

Reduce Risk

- Market testing

- Use the most updated version of the package

- Reduced time-to-market

- Volume-based demand

- Global colour management

- Anti-counterfeit components

- Print quality Regulatory compliance

More value to consumers

- Reduced time-to-market

- Deliver localized versions

- Cause driven promotions

- Event-driven promotions

- Late-stage product differentiation

- Product life cycle solutions

Environment

- Reduce waste

- Reduce carbon emissions

- Reduce obsolescence

- No hazardous chemicals

- Reduce energy consumption

Supply Chain

- Track & Trace

- Serialization

- Revision control

- Warehouse & distribution

- Just-in-time production

Request a Pouch Sample Pack

Stand Up Pouches

As the name suggests, this packaging stands up on the shelf providing high product visibility.

Bakpac at baker labels

If you’d like to know more about how BakPac can supply you with flexible packaging please get in touch.

If it’s labels you’re after please visit us at Baker Labels.