BakPac Story

BakPac is a flexible packaging manufacturer. As part of Baker Labels we have over 50 years of print experience and trade ethics that are second to none. We print and produce short to medium runs of stand-up pouches, pillow pouches and printed film for customers looking for a high speed to market option for their products.

As a successful and long established trade label printer, why did Steve Baker decide to branch out into flexible packaging?

“It was big step to move into the manufacture of flexible packaging so we planned this for a couple of years. Making the equipment investments, designing the factory refurbishment and the training and educating of our staff all took meticulous planning and a lot of time. However, it’s been a brilliant journey and we’ve had great support from HP, ABG and Karlville along the way. I’m more than confident that it’s the right decision for Bakers and I’m excited about the future.” Steve Baker, managing Director of Baker Labels.

January 2018

The neighbouring unit to Baker Labels became available at Hubert Road in Brentwood. This provided an opportunity to expand the premises that Bakers had moved into in April 2011. At the time the need for more space was not necessarily there but, with Steve Baker’s ethos of continual investment, he knew it wouldn’t be long before it would be.

June 2019

Phil Smith joins Baker Labels as the new General Manager of BakPac [read more]

“I am delighted to become part of the Bakers team who are highly skilled and passionate about the customer base. Their continued investment, growth and technical development is second to none.

The prospect of joining the Bakers business and running such an exciting project was too good to resist, having seen the evolution of digital in the labels industry and understanding what benefits it would bring to the flexible packaging market I wanted to be a part of that journey.”

July 2019

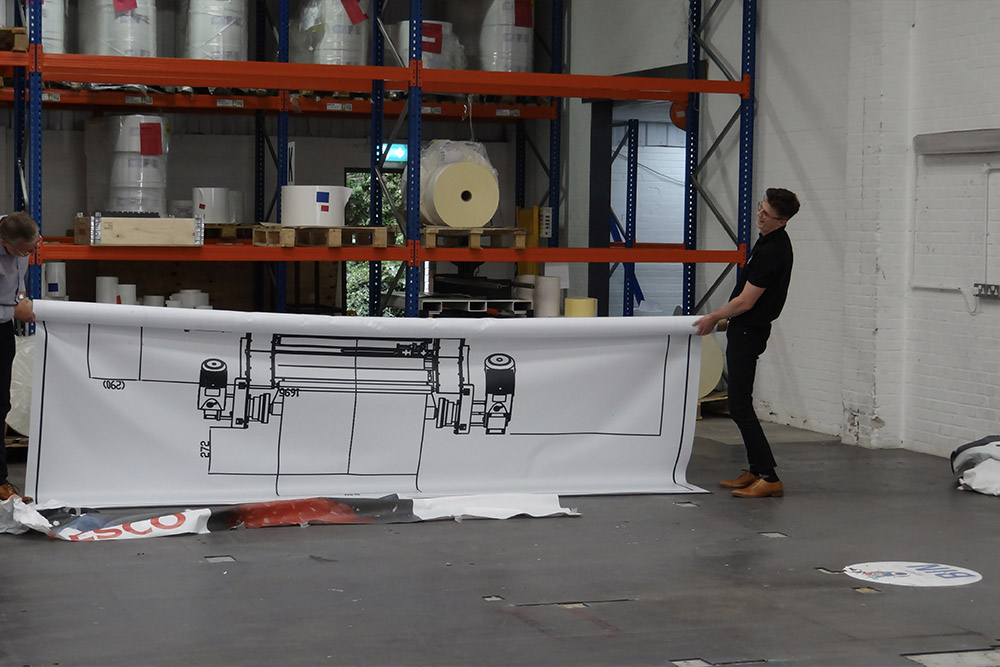

The central unit at Bakers is cleared and planning for the layout of the new BakPac facility is assisted by the production of full scale floor images.

August 2019

The HP 20000 was the first major investment for the BakPac plan, being delivered and installed in August 2019. It was then wrapped up for protection as the factory and BakPac facility was refurbished and constructed around it. Baker Labels already produces labels on 3 HP Indigo 6900 presses and has a long established relationship with HP. They first digitally printed labels on an HP 4050 in 2006 so it was a natural progression with the move to flexible packaging to continue the investment with HP.

The HP 20000 is a proven application fit for food packaging. With technology such as HP Smartsteam Mosaic and Collage it can offer variable images, data and brand protection. In addition, HP ElectroInk is fit for use in compostable and recyclable packaging.

September to November 2019

Over the course of the next few weeks the central unit within Baker Label’s facility went through a major refurbishment to install the “clean room” BakPac facility. To manage the additional power supply required we also had to install a whole substation in the car park. Limiting onsite staff parking for a few weeks was a bit of a drama!

November 2019

Karlville delivery and installation

For the conversion of the printed, laminated film we invested in the first ever dual web Karlville Pouchmaker. As well as the expected folding of a wide web of material to create a pouch with doyen or K-seal, this Karlville allows the production of pouches with different materials on the front and reverse as well as another for the gusset. It has a very low scrap rate during machine start-up, changeovers and roll changes therefore reducing waste.

December 2019

Enprom Thermal Laminator delivery and installation

Enprom is a company of A B Graphic International and Kocher & Beck. Baker Labels has a long established relationship with A B Graphic, with a fleet of Digicon presses for label embellishments and finishing. So when Steve Baker heard of the connection to Enprom he knew they would be able to manufacture a thermal laminating machine suitable for the digitally printed flexible packaging market. Steve worked closely with Matt Burton and the Enprom engineers as they designed and built their first ever thermolaminating machine. The press was delivered to Bakers in December 2019.

February 2020

Baker Labels launches BakPac for Digitally Printed Flexible Packaging

Brentwood’s Business of the Year, Baker Labels, officially added a new flexible packaging arm to the company with the launch of BakPac. BakPac will manufacture digitally printed flexible packaging in the form of stand-up pouches, pillow pouches, shrink wrap and printed film.

BakPac was officially opened on Thursday 12th February with a ceremonial ribbon cutting by Marian Baker, who founded Baker Labels with her husband Roy in 1973. The event was attended the Deputy Mayor of Brentwood Cllr Olivia Sanders, former Mayor Mrs Sheila Murphy, Deputy leader of Brentwood Council Noelle Hones, representatives from Bakers’ supported charities SNAP & Kids Inspire along with Head of Business Studies at Brentwood School Mrs Kelly Giles, retired Baker employees and other invited guests.

January 2023

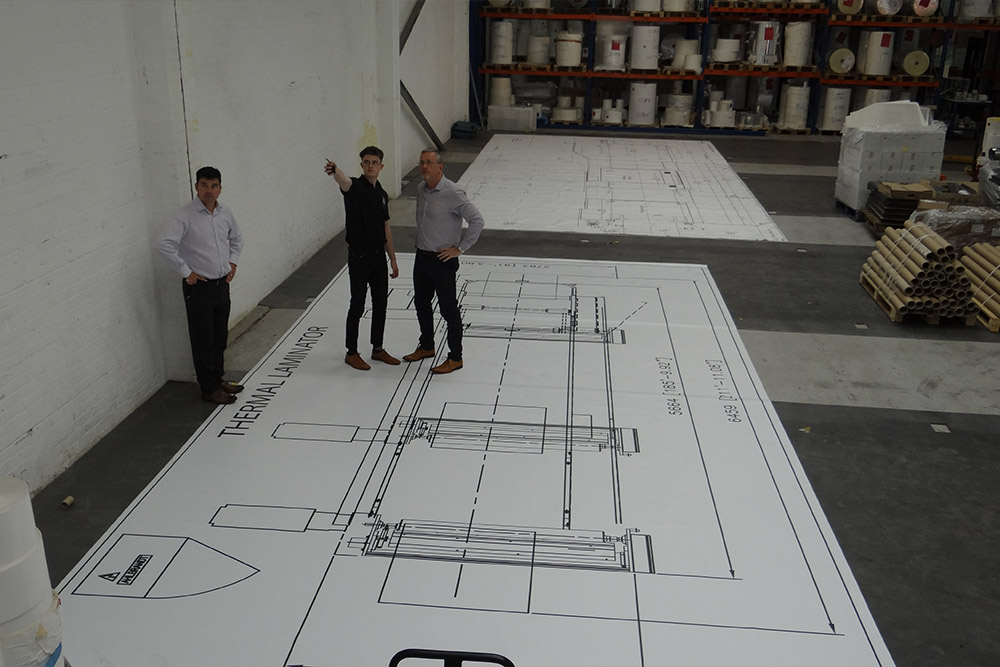

A B Graphic Digicon 3000 delivery and installation

In our continued commitment to invest in new equipment and technologies, we expanded the finishing capabilities of our digital pouch production facility, BakPac, with a Digicon 3000 from ABG and Edale.

What is a Digicon 3000?

The Digicon 3000 is a wide-web digital finishing and converting solution, offering web widths between 400-762mm. It was designed and manufactured in partnership between ABG and Edale, specialists in flexographic print, web transportation and post-print converting.

August 2023

Installation of Galaxy Pouchmaker

In August 2023 we took delivery of our second pouch converter to boost our production line. The investment decision was driven by a demand from customers for a wider range of shapes and sizes on top of the growing need for capacity and speed.

The new Galaxy pouch converter gives the BakPac production team the added capabilities of producing:

- pouches with side gussets

- shaped pouches

- extended range of sizes of stand up pouches

- variety of zipper options including velcro, track and pocket zipper

- Read more

January 2024

Factory Expansion with a new Unit

With a growing demand for digitally printed flexible packaging and the ambition to expand further into the sector, we took on the another factory unit on Hubert Road.

By the end of the year this unit will house all pouch finishing equipment. All pouching lines, spouting lines and valve insertion.

January 2024

HP Indigo 200K Installed

Stepping into the heart of BakPac’s operations, the HP Indigo 200K boasts a 30% increase in printing speed and a staggering 45% boost in expected productivity. This isn’t just about numbers; it’s about pushing boundaries in packaging manufacturing, with quicker turnarounds, unparalleled efficiency, and the ability to handle diverse printing requirements with ease.

Market Positioning

BakPac proudly stands as the first UK production company to house the Indigo 200K, also making it an exclusive HP reference site.

Clients, both existing and new, stand to gain significantly. The HP Indigo 200K promises continued and consistent print performance. For clients seeking higher quantities with the same advantages of digital printing, BakPac’s expanded capacity is a game-changer.

June 2024

Second Galaxy Packtech Pouchmaker Installed

Technical Advancements of the Galaxy GS-24 Plus-200

There are some key advancements to this new pouching line compared to the one it is replacing:

• It will have the ability to run 2 up stand-up pouches with zippers on the same web – doubling production and reducing set-up time and waste.

• New sealing capability to further improve our Mono polymer pouch production

• Advancements in the gusset assembly to allow a greater size range in our folded gussets

• General design updates to enable even higher quality pouches along with improved efficiencies

• Full contingency for side gusset pouch production

November 2024

Third Galaxy Packtech Pouchmaker Installed

BakPac expanded its flexible packaging capability with the installation of a third Galaxy Packtech pouchmaker in the new production unit. The addition boosts efficiency, delivers even greater sealing and quality, and supports sustainability by handling mono-materials, cutting waste, and enabling recyclable pouch production.

May 2025

Fourth and Fifth Galaxy Packtech Pouchmakers Installed

BakPac further expanded its flexible packaging capabilities with the installation of two additional Galaxy Packtech pouchmakers in May 2025. This strategic move enhances production capacity, enabling faster lead times and reinforcing BakPac’s commitment to delivering high-quality, recyclable packaging solutions.

May 2025

Over 1 Million Pouches Produced in a Week

Thanks to our expanding fleet of Galaxy Packtech pouchmakers, BakPac hit a milestone by producing over 1 million pouches in a single week. All those new machines we’ve been installing clearly weren’t just for show! This achievement highlights our production capacity, efficiency, and ongoing commitment to delivering high-quality, recyclable packaging.

Bakpac at baker labels

If you’d like to know more about how BakPac can supply you with flexible packaging please get in touch.

If it’s labels you’re after please visit us at Baker Labels.